charpy impact test journal|charpy impact test diagram : importer The Charpy impact test has been simulated based on the determined parameters combined with the trial algorithm method. According to the test results, the strain rate related .

WEBEndereço. Q 46, Conjunto B, Lote 04 N° 46 Parque da Barragem - Águas Lindas - CEP: 72910-001

{plog:ftitle_list}

Estatísticas da Mega-Sena atualizadas até o sorteio: 2692 - Dia: 24/02. Os cinco números que mais saíram e os cinco números que menos saíram na Mega-Sena. Vezes .

Charpy tests. Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy .Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding .The Charpy impact toughness of aluminum alloys is reduced via introduction of the .

The Charpy impact test has been simulated based on the determined parameters .

The Charpy impact test is one of the most popular tests used to characterize the . The Charpy impact test has been simulated based on the determined parameters combined with the trial algorithm method. According to the test results, the strain rate related . The Charpy impact test is one of the most popular tests used to characterize the mechanical properties of structural materials, particularly steels, for the fabrication of industrial .

A 4 K Charpy test is defined as a Charpy test in which the initial temperature of a specimen is 4 K. Two methods, a glass Dewar method and a flow method, are compared in this study to . Charpy impact testing is a low-cost and reliable test method which is commonly required by the construction codes for fracture-critical structures such as bridges and pressure . Then, the effectiveness of the model through a series of impact tests is verified. Theoretical analysis and experimental results show that the relationship between ligament . This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen sizes and geometries. Additionally, some studies .

The paper presents and analyzes the results of experimental tests performed on two non-alloy low carbon steels (1.1141 and 1.0122) in cases of their exposure to impact fracture energy and uniaxial high cyclic mechanical stress .

charpy impact test standard pdf

Charpy impact test is one of the most important tests to study impact toughness due to its simplicity and rapidity. It can be used to explain the mechanism of impact fracture .Charpy impact test was developed in the 1960's as a method of determining the relative impact strength of metals. It is a standardised high strain-rate test that can measure the amount of energy absorbed in a material. . an instrumented Charpy impact machine. International Journal of Fracture 2005, 132:81–97. [3] Rossoll, Berdin.C and .

plating thickness tester manufacturers

Journal of Materials Research and Technology. Volume 25, . Charpy impact test's ability to detect an intentionally introduced defect in a tested sample is studied, involving exploitation of force-displacement data recorded during the test on reduced-size samples. For a defect localized within the notch plane, the results show that reduced .In a Charpy impact test, three key measurements are typically made: total absorbed energy, lateral expansion, and percent shear fracture area. At present, the measurements of absorbed energy and lateral expansion are quantitative and well defined, but the methods used by most laboratories in the measurement of percent shear are qualitative at best.Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.

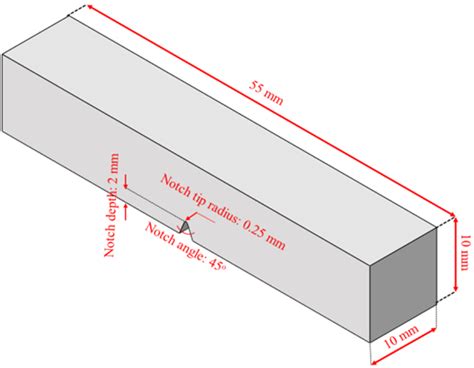

Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).Cite this chapter. Subhash, G., Ridgeway, S. (2018). Charpy Impact Testing. In: Mechanics of Materials Laboratory Course. 2.1 Charpy Impact Test. Charpy impact test is conducted according to GB/T 229-2020 and ASTM E23-2018. Standard V-notch specimens are adopted in the test, and the profile dimensions of the specimens adopt herein are the same. The test specimen is shown in Figure 1(a), and the geometric sizes are shown in Figure 1(b). The length of impact .

charpy impact test standard

Abstract. This paper is focused on the approximation of absorbed Charpy impact energy-temperature curves (KV-T) and the management of sub-size test piece results in Charpy pendulum impact tests. Both subjects are frequently underestimated but may have a strong impact on the assessment of product quality and structural integrity. The status of related test . 1. Introduction. Impact energy characterizes the ability of a structure to consume energy through deformation and fracture under impact load. The impact energy A k, a value measured by the Charpy impact test, is mainly used to control the quality of metallurgical and thermal processing products and determine the ductile-brittle transition temperature of .

Charpy Impact Test on Mild Steel (Mohammad Jassim Hussain) ABSTRACT The overall purpose of this research is to explore the usage of an impact testing machine, specifically the Charpy . International Journal of Engineering Research and Applications www.ijera.com ISSN: 2248-9622, Vol. 11, Issue 10, (Series-IV) October 2021, pp. 59-63 The Charpy impact test performance was experimentally and numerically studied for two advanced high-strength steel sheets (AHSS) TWIP940 and TRIP590 as well as for a high strength grade 340R. Uni-axial simple tension tests were performed to determine their anisotropic properties and strain rate sensitivities along with their hardening behaviour. The high speed .

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.

The Charpy impact test can adequately detect this brittle-toughness transition temperature, providing key data on the material’s limits of use. It must be noted, however, that the Charpy test is less useful for comparing the toughness of different metals but is more suited to providing information on the behavior of a single material at . The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a .

The fracture toughness could be predicted from Charpy impact test results, on the lower shelf, by applying the `local approach'. . Mechanism of deformation and fracture in the Charpy test as revealed by dynamic recording of impact loads. Journal of the Iron and Steel Institute 912–920. Fisher, J. and Gurland, J. (1981). Void nucleation in . Several researchers have recently employed the Charpy method to characterize the high strain rate mechanical strength of cementitious composites. This paper provides a critical review of existing applications of the .

The Charpy impact test is used to determine the impact toughness or impact strength of a certain specimen. The apparatus used are the Zwick Roel Charpy testing machine and a V-Notch Charpy type specimen. . View the table of contents for this issue, or go to the journal homepage for more Download details: IP Address: 177.221.163.9 This content .

charpy impact test sample

In this study, gas metal arc welding (GMAW) was used to construct a thin wall structure in a layer-by-layer fashion using an AWS ER70S-6 electrode wire with the help of a robot. The Charpy impact test was performed after extracting samples in directions both parallel and perpendicular to the deposition direction. In this study, multiple factors related to the resulting absorbed .In this paper, instrumented impact test results obtained using V-notch and precracked Charpy specimens of AISI 308 weld and AISI 316 stainless steels are analysed for determining the plastic η-factor for three-point bend specimens used in J-integral evaluation. Tested 316 stainless steel specimens were in various thermal aging/cold-work conditions whereas 308 weld specimens .

The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value. Further, the other samples were machined for the Charpy impact test as suggested by American Society for Testing and Materials A370 10 mm × 10 mm ×55 mm with a 45°, 2 mm deep V notch at the center having a base radius of 0.25 mm. For analyzing the results through MATLAB, the neural network is utilized. . International Journal on .

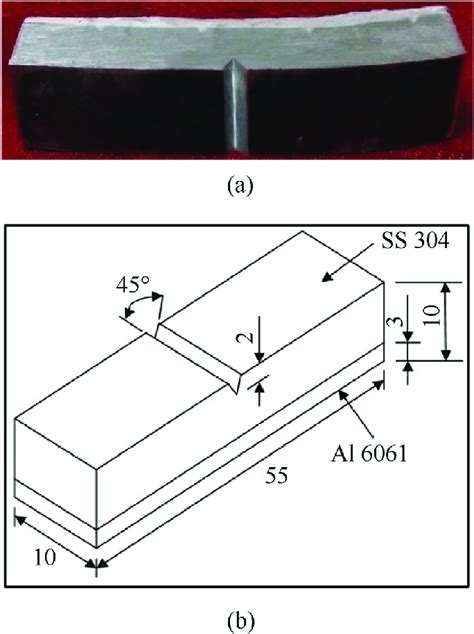

In this paper the influence of notch acuity and test temperature on the impact behavior of aluminum alloy 6061 is presented and discussed. Notch angles of 45°, 60°, 75° and 90° were chosen for a standard charpy impact test specimen containing two such notches positioned at right angles to the applied load. For a given angle of the notch the dynamic fracture toughness .

Instrumentation of the Charpy impact test permits an analysis of the data in terms of linear elastic fraeture mechanics. Measurements of time to fracture are converted to estimated crack opening displacements at fracture and thus to values of the fracture toughness parameter KC. The variation of these values with temperature shows a transition which is interpreted as a .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).Specimen Size on Charpy Impact Testing J. Nucl. Mat. 155(157) pp 662-667 [9] Lucon E, Chaouadi R, Fabry A, Puzzolante J-L and Van Walle E 1999 Characterizing Material

plating thickness tester price in india

The paper presents and analyzes the results of experimental tests performed on two non-alloy low carbon steels (1.1141 and 1.0122) in cases of their exposure to impact fracture energy and uniaxial high cyclic mechanical stress-controlled fatigue. The experimental results provide insight into the changes in the Charpy impact fracture energy of the V-notched test . Charpy tests were performed on a modified Riehle Impact Testing Machine, which was instrumented to detect small changes in hammer velocity (Fig. 1).Standard Charpy machines operate from two drop heights, 61 and 122 cm (24 and 48 in) with two hammer masses so that four impact energies can be obtained, 41, 81, 163, and 325 J (30, 60, 120, and 240 ft-lbs).

plating thickness tester suppliers

webThe trust score of intel-academy is very low. Why? The trust score of intel-academy.com is extremely low. This is a strong indicator that the website may be a scam. We rated intel-academy.com using a computer program.

charpy impact test journal|charpy impact test diagram